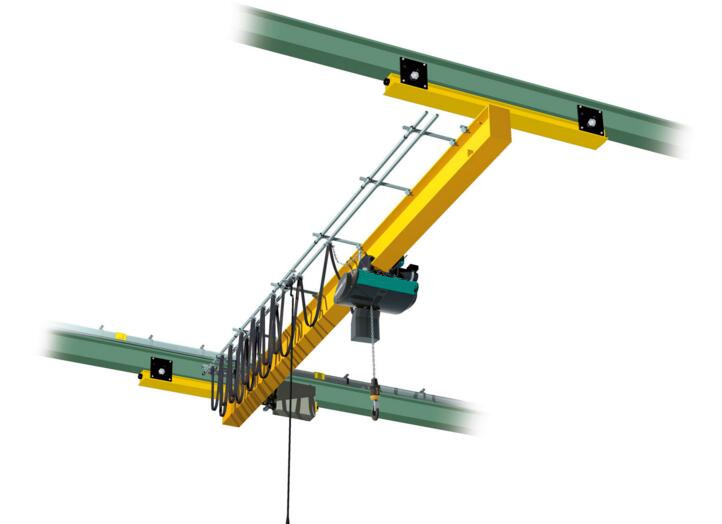

An overhead travelling crane is a great machine to get. Once you place a competent operator facing a crane like this, it’ll be easier for you to boost several tasks.

But while using a skilled operator is always a good thing, you just might care for some tasks without. Today’s cranes may be loaded up with a range of smart features, which can automate and simplify a variety of processes.

Below are a few of your features you should seek out when buying a crane:

1. Security Features

Safety is always of your utmost priority when working with industrial equipment. However, also a well-trained operator is just human they might get some things wrong sooner or later.

Should you buy a overhead crane solution that comes with security features, it can keep those small mistakes from turning right into a serious problem. The crane will be able to tell when something is wrong, and prevent or send a warning as required. It’ll ensure that the job you require done is definitely completed correctly.

2. Control Features

Some overhead travelling cranes of Ellsen can mostly automate the movement of the crane. It’ll work to make sure that the crane always moves in the perfect way.

Whenever your crane’s movement is optimized, you will have less strain positioned on its components. Your 25 ton overhead crane lasts longer and desire less maintenance in the future. In addition, features such as this can increase the safety of your respective crane. This really is a feature that can benefit you in several alternative methods.

3. Snag Prevention

Cranes can frequently get caught on something, regardless of whether safety measures will be in place. This can harm the crane, and cause some headache-inducing slowdowns.

When you have snap prevention, the low price overhead shop crane will immediately stop if it’s caught on something. Workers will be able to resolve the issue before it gets any worse. What could have been a big issue will instead be considered a minor inconvenience.

Just click here to scan various kinds of overhead travelling crane with advanced technology and reasonable price. http://ellsenoverheadcraneservice.com/overhead-traveling-crane/

4. Sway Control

Heavy loads can often swing while they go over the ground. Furthermore this make a load less stable, it endangers anyone who is one the soil below.

Thankfully, a great deal of today’s electric overhead travelling cranes could be provided with sway control. This limits load swing and helps to ensure that a crane will always be as safe as you possibly can.

5. Assisted Load Turning

Turning a crane is probably the biggest challenges operators face. Side pull could be a major issue. Luckily, when a high quality magnetic overhead crane comes provided with an assisted load turning feature, operators won’t have to deal with load turning alone. They’ll possess the assistance they need to complete the work perfectly.

As you can tell, you will find a myriad of impressive smart features accessible for overhead travelling cranes. Determine which features you’d like your crane to have. These functions may cost you up front, but over time, they should certainly help save you a lot of time and money.

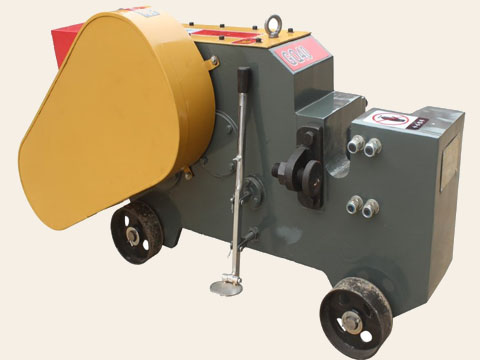

not most — designs, wires are more easily incorporated into a completed assembly when they can be installed pre-shaped to fit their space. While this was once painstakingly accomplished by hand during the installation process itself, today it is a task that can be easily automated. This is the job of CNC (Computerized Numerical Control) wire bending machines.

not most — designs, wires are more easily incorporated into a completed assembly when they can be installed pre-shaped to fit their space. While this was once painstakingly accomplished by hand during the installation process itself, today it is a task that can be easily automated. This is the job of CNC (Computerized Numerical Control) wire bending machines. These machines can be either very simple or exceedingly complex, but the basic principles are the same. An automated wire feed mechanism pushes wire stock onto a bending jig. It encounters one or more pins, rollers, or other shaping forms to bend it as it advances. These forms are typically mounted to a mobile cam. By adjusting the speed of the wire feed and the position of the forms,

These machines can be either very simple or exceedingly complex, but the basic principles are the same. An automated wire feed mechanism pushes wire stock onto a bending jig. It encounters one or more pins, rollers, or other shaping forms to bend it as it advances. These forms are typically mounted to a mobile cam. By adjusting the speed of the wire feed and the position of the forms,  Modern CNC wire bending machines can be created to handle advanced tasks beyond simple wire bending, including cutting, welding, reshaping, and flattening. Many are even built to handle three-dimensional bending, a feat that can significantly reduce the number of manufacturing steps required to produce a finished shape.

Modern CNC wire bending machines can be created to handle advanced tasks beyond simple wire bending, including cutting, welding, reshaping, and flattening. Many are even built to handle three-dimensional bending, a feat that can significantly reduce the number of manufacturing steps required to produce a finished shape.

0