It won’t be wrong to say that today’s modern world revolves around hydrocarbons. Hydrocarbons are used for fuel and for creation of plastic among other uses. The use of plastic has become so prevalent that landfills full of plastic all over the world have become a big problem.

One of the biggest problems with plastic is that it is not biodegradable which means that it just keeps lying there. It is estimated that plastic takes around a million years to decompose. However, things have changed with the advent of waste pyrolysis plant that can help in converting plastic into oil.

In the pyrolysis process, the scrap plastic is heated in absence of oxygen to a temperature of more than 370 degrees C. In this process, the scrap plastic is not burned but it is chemically converted into various other useful products including pyrolysis gas, pyrolysis oil and carbon black. All of these products are in demand and can be easily sold.

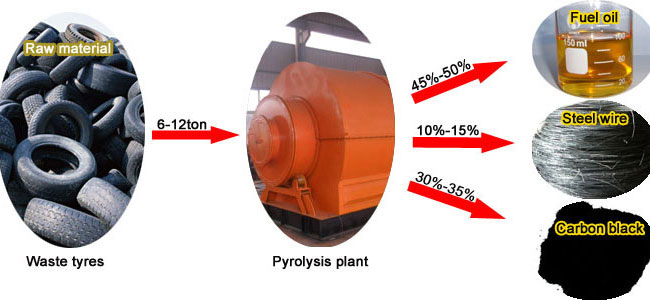

The gas produced during the process is used for heating the waste plastic. A high quality pyrolysis plant can produce around 650 to 900 L of pyrolysis oil, 50 to 70 kg of carbon black and 50 to 100 kg of hydrocarbon gas from just 1000 kg of waste plastic scrap. Also, these plants can use a variety of plastic materials for the pyrolysis process.

The raw materials include waste plastic, electronic scrap, waste plastic, tires, waste engine oils, plastic from vehicles and various other sources. As far as the cost of pyrolysis plant is concerned, one should take a look at the return on investment.

A number of research studies have been conducted to study the business of converting plastic into oil and most of these studies have concluded that the plant returns the initial investment within a period of 12 to 15 months. In simple terms, one can get back the initial investment within just 15 months and then the plant will keep delivering profits for years to come.

As far as the actual plastic to fuel plant cost is concerned, it depends on the kind of machine one wants to buy. There are a number of manufacturers selling these machines. Most of these manufacturers are based in India as well as China. It is important to keep in mind that the quality of machine varies a lot as some of the machines can take in all kinds of plastics whereas some others are unable to process certain kinds of plastics. Here is a video of continuous pyrolysis reactor.

Therefore, one needs to buy a machine keeping in mind the type of raw material that is going to be used for the pyrolysis process. The operation of machine is very simple. A worker will need to shred the raw material and feed it into the reactor. The reactor will keep processing the raw material for a period of around 8 to 12 hours.

The gas produced during the process can be rerouted to reheat the raw material in the reactor. Overall, a waste plastic to oil machine is like having access to an oil field that keeps producing various types of oils on an ongoing basis. No drilling or exploration is required. The only thing needed to operate the plant is waste tires and plastic.

We did our research and found that waste tire recycling machinery for sale is not cheap, and even if you buy one that’s made in China, it can set you back by $37,000 to $140,000. But then again, expensive is something relative, and what is expensive for some people may not be expensive at all for others. Accordingly, you need to find a reliable

We did our research and found that waste tire recycling machinery for sale is not cheap, and even if you buy one that’s made in China, it can set you back by $37,000 to $140,000. But then again, expensive is something relative, and what is expensive for some people may not be expensive at all for others. Accordingly, you need to find a reliable

0