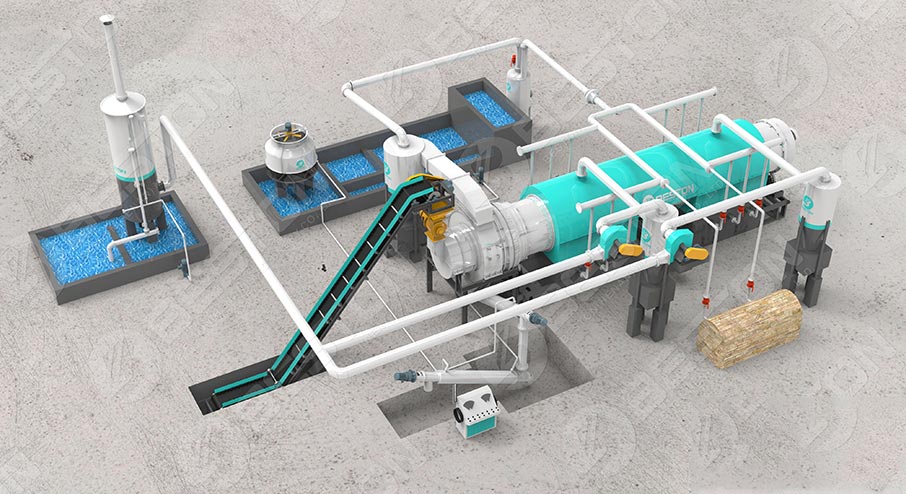

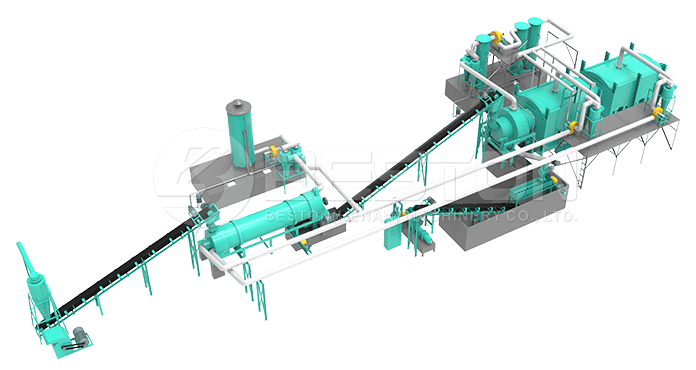

The biomass to charcoal making machine is indeed a revolutionary machine for sale in the industry. These machines tend to make use of the most advanced carbonization tactics known to man to convert biomass to charcoal. The machinery produced by the leading manufacturers has been installed in several places around the globe and they’ve been known for also producing a hefty profit. So, read on as we dive into everything that you’ll need to know about the biomass to charcoal making plant.

If you didn’t already know, the biomass machine (maquina para hacer carbon vegetal)makes full use of the agricultural wastage and it also produces the waste from the forests. The machine simply processes the likes of sawdust, fruit hush, cellulose, coconut shells, logs, tree bark, palm shells, and other products that are rich in lignin. All of those mentioned and more are produced into charcoal, combustible gas, tar, and wood vinegar.

In essence, a ton of biomass materials can be processed in the machine. As previously stated, some of these include but are not limited to the following:

* Coconut shells, palm shells, rice husk, bamboo, sawdust, wood chips

* Industrial sludge, municipal sludge, civil sludge

* Food waste, municipal solid waste

When the materials above are processed, they then form those listed below:

* Charcoal

* Wood vinegar

* Tar

* Combustible gasses

In the case of the uses, the charcoal produced can be used as a fuel source and it can also be used as BBQ charcoal(hornos metálicos para hacer carbón). In the agricultural sector, the finished products can also be used to improve the soil quality and it significantly enhances the grain output. In terms of an industrial setting, charcoal can sometimes be reprocessed.

Reprocessing of the charcoal leads to the following byproducts:

* Fuel for both iron and steel factories

* Ceramics

* Pesticides

Besides everything already mentioned, these machines were designed with the environment in mind. As such waste products are recycled and converted into various useful products. Additionally, the wood vinegar and tar are both treated with combustion control to ensure that it is both environmentally friendly and safe.

The syngas produced is also treated by a specially designed multiple dust removal device. This ensures that it meets the regulated emission requirements. The machine allows both natural gas and diesel to be used for the preheating process and the overall service life is a whopping 12 years.

In the case of sewage, this adopts what is known as sedimentation tech. This enables it to be reused. Hence, sedimentation sludge is now becoming more and more popular. The all-new state-of-the-art design also makes the machine(https://www.bestoneco.com/carbonizacion-bst-30-enviada-a-mexico/) very energy efficient.

Hence, both frequent conversion tech and intelligent equipment control make it energy saving. The double drum feature also makes preheating drying a useful feature. Hence the overall thermal efficiency is much higher.

These machines(Detalles de la empresa Beston) were designed with the environment and energy conservation in mind. Additionally, it also saves on resource wastage and the overall efficiency is higher!

0