This innovative technology has come up with the procedure of converting tyre to oil as well as plastic, used to run commercial machinery. This is done with the very knowledge of chemistry used in converting non-recycled plastics into the petroleum based products. These technologies have succeeded in complementing the ongoing processes of recycling. This drives a new economic trend as clean energy can be derived from the otherwise waste material. Investment plants and implementations have been made on the technologies and thus have succeeded in driving the economy of involved countries. This excerpt will briefly explain plastic to oil pyrolysis technology; afterwards state its importance in the economy.

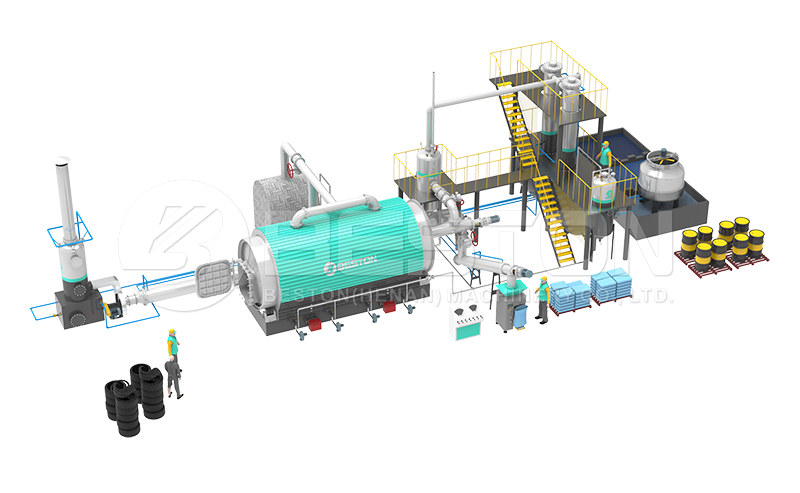

The common process involved in conversion starts by a level of pretreatment of the plastics. This is a mild form of removing impurities and moisture. Pyrolytic process follows, where the plastics are heated without oxygen to convert the material into gas. the working process of oil distillation plant follows. This is where the gas is converted to liquid form, where they are separated into oil, fuels and other petroleum products. This is a very simple procedure whose end products are used by manufactures and others used to fuel heavy machinery such as vehicles and airplanes. Here is a video for you:

Successful use of this technology has been witnessed in various parts of North America, though no commercial systems have yet been implemented in the area. However, some organizations in Canada and the U.S A have run pilot operations that have proved to be a gold mine. Reports suggest that orders have already been placed for some commercial systems; this is a perfect indication that this technology is the next big thing in the face of the earth. It is witnessed that most investors have eyed the technology and are confident about its viability to fit the future market; therefore it is a promising project that will see to it that the environment has been saved.

Facility locations engaging in this type of technology have been established around various developed countries in the recent past. Countries like China, Japan, Ireland, Korea, Australia, Poland and Singapore among others have established the plants whose end product is pyrolysis oil from plastic waste. These companies boast to being the pioneers of such technology in the 21st century, amid global warming and the mess of plastics being the main source of threat in polluting the environment. If you want to know more details about the pyrolysis oil technology, please visit the website here: https://mswrecyclingplant.com/waste-pyrolysis-plant/.

It is recommended that states and government should embrace this technology as it proves to be another form of green energy. They should be recognized to complement the recycling process. The law should also view this type of technology as an alternative source of energy rather that a method of disposing waste materials. The technology should also be viewed as a 21st century innovation, and regulations concerning the same should be made. With the adoption of plastic-to-oil technology, production of greenhouse gases will be reduced drastically by up to 60-70%.

In conclusion, the plastic to fuel machine has proved to be promising to fit in the next generation as it will succeed in providing fuel oils, electricity, lubricants, other plastics, petrochemicals and crude oil, thereby driving the economy in the right direction.

0