When you work in the construction or building industry, you are going to need to learn about dry mix mortars. These mortars are made with sand, cement and other additives. Each bag of mortar is precisely weighed and comes in a special bag where it can be used in a dry mix plant. Read on to learn more about dry mix mortars.

Click http://aimixconcretebatchingplant.com/vitrified-micro-bubbles-production-line/ to buy one inorganic thermal insulation mortar production line right now!

Dry mix plants typically use multiple types of mortar in their operations. The mortar can even be formulated in the dry mix plant. It is faster and more efficient to use dry mix mortars because they offer consistent quality. Having consistent quality is important when you are engaging in construction projects because you have to make sure that the projects are going to meet building codes and standards. You can’t have a strong building made out of shoddy materials.

Bagging dry mix mortars also offers controlled inventory so you always know what you have at any given time. With dry mix mortars you know that you always have always have enough of what you need and you don’t have to worry about being caught short. When you don’t have enough materials, construction projects have to be put on hold which costs you money and time. When you are in the construction industry, you don’t have time to be down for long so it is important that you are always stocked with the right materials.

Or click Aimixconcretebatchingplant.com// to find more information about dry mortar production line here.

Having dry mix mortar ready to go will also save time and it will save labor cost. When you have the mortar already bagged and mixed, you don’t have to pay your employees to do it for you which saves money and saves time. Anything you can do that will save you money is a good thing and you want to always save money wherever you can.

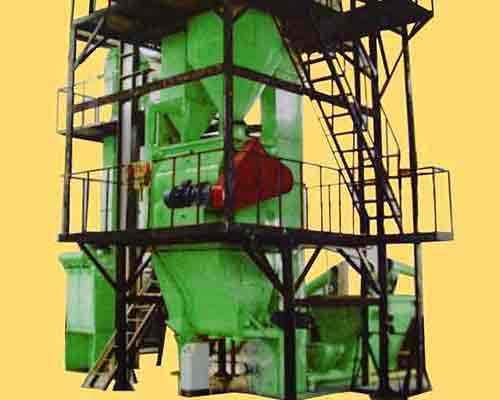

Dry mix plants make the mortar and you can almost full automate your plant. You only need one operator to operate the dry mix plant and all the functions of the plant can be controlled by computers. The plants can also be customized to ensure that you are getting exactly what you want.

The mixers in the plant will control how much dry mortar mix is produced and the kind of quality it is. The mixers also allow you to add in special additives so they are blended uniformly. This ensures that your your dry mortar mix is consistent.

Vitrified micro bubble mortar contains special beads that make it lighter. It also has a high bond strength and it sets up quickly. This type of mortar exhibits good performance and it has a low shrinkage rate which is important. Vitrified micro bubble mortar prevents condensation and has no cold bridge.

Producing the right type of dry mix mortar is essential and the right plant will ensure that you get the right mortar mix each and every time. When you have consistent and stable mortar, every aspect of construction becomes much easier to produce.

0