Do need to buy a tissue paper making machine in the next few weeks? Perhaps you have had one go out recently. It is difficult to find a company that will be able to provide you with ones that are exceptional and also at an affordable price. It is so important to do a little bit of research, looking for companies that also produce cylinder mold paper machines and those that do toilet paper. If they have a wide variety of choices, you will certainly be able to find one that is extremely affordable. This is what you need to do in order to get a tissue paper making machine price at the best price.

Why You Can Find One On The Web Easily

You can find one that is on the Internet very quickly by looking at websites where they are listing industrial equipment every day. The type of equipment that they offer, and the places that it will originate from, can help you make the right decision. The amount of time that you spend searching for these fourdrinier machine companies can be very minimal. There are only a few that are exceptional in this industry. You will soon be able to contact one of these businesses that will be able to sell you one at an affordable price.

What Do These Machines Do?

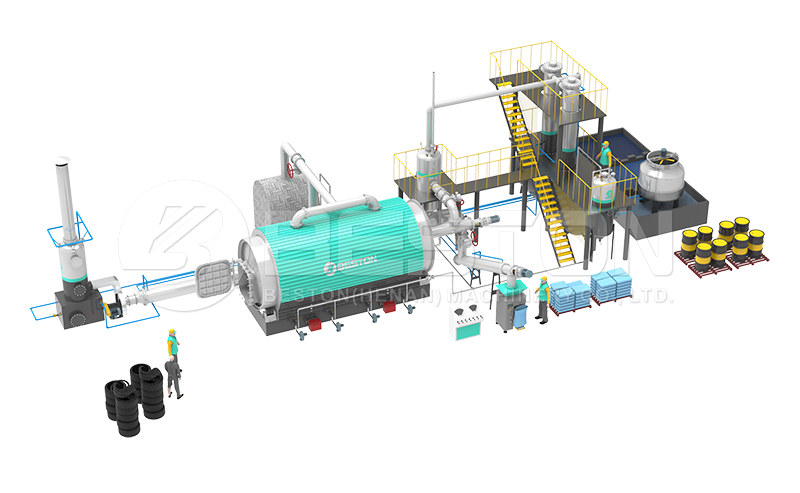

These machines are designed for making tissue paper that is used all over the world. This could be anything including napkins, paper towels, facial tissues and tissue paper. It is very easy to evaluate them based upon how much output they have, their weight, and the end paper dryness. These are the factors you will want to consider as you are choosing one of these machines. You should also consider its overall weight as this can factor into the cost of shipping it. The net paper with and working speed are also important factors. Once you have gone over all of this, and you have found several that look promising, simply order one from a paper machine manufacturer that has a great reputation that will sell it to you for an affordable price.

How To Know You Have Selected The Right One

You will know that you have chosen the right cylinder mould paper machine business when you see multiple reviews on the Internet that are clearly showing that people are advocating this particular product. These are probably businesses just like you that are producing paper products that are sold all over the world. If they have given this their approval, it will likely work for you.

Once you have found the right tissue paper making machine price, you should be able to place your order and have it delivered soon. If you already have several, you simply need to find a place where you can position it so that you can increase your production levels. If you have not been in this business before, it may take a little bit of time to acclimate to how it works, how much output it will actually put out and waste paper recycling plant cost. This will make it easy for you to quickly find a company, usually one in the Orient, that will have the best selections at prices that will be well within your budget.

0